Franz Arlart, Lucca Brüggemann and Dennis Bui published in the Industrial Building Award 2018

CONCRETE SHELL -

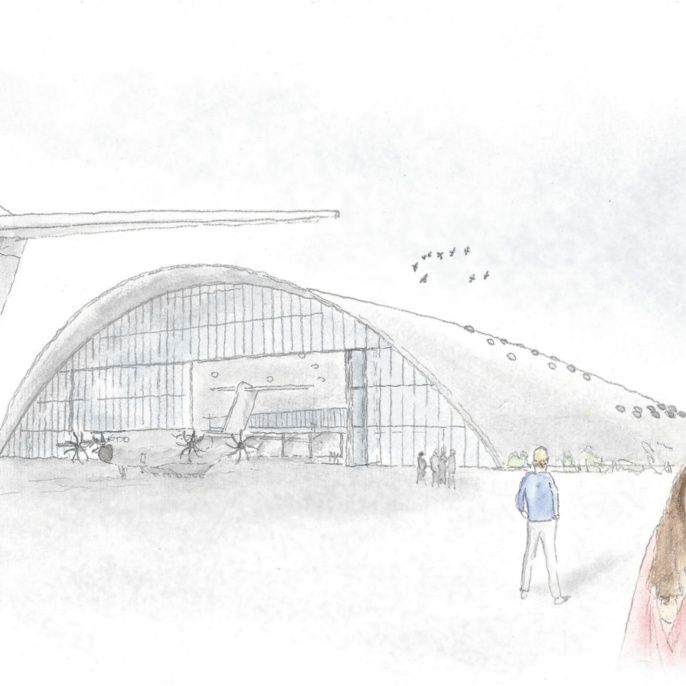

FILIGRANE CONCRETE SHELL HANGAR FOR A400M

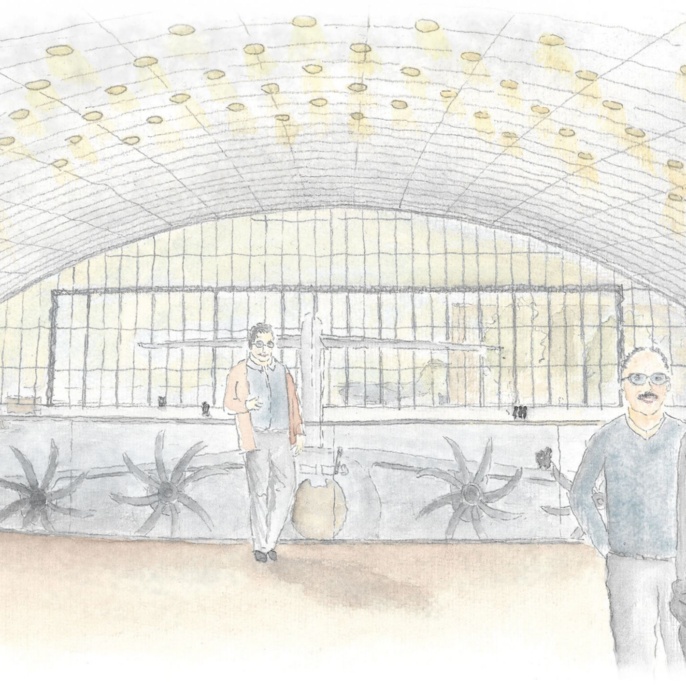

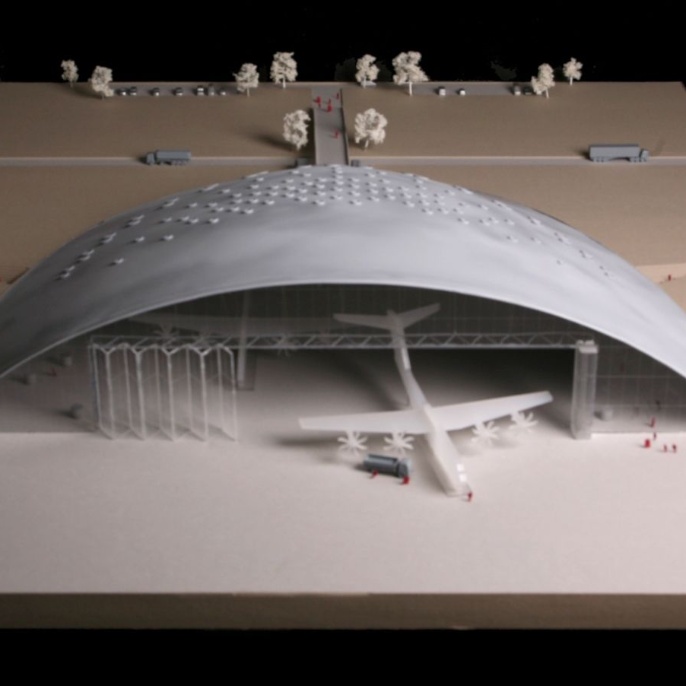

Flying and airplanes have always been topics that deeply engaged mankind. With their invention, life has changed fundamentally. Now architectural structures have to do justice to this achievement in aesthetics, expression and construction.

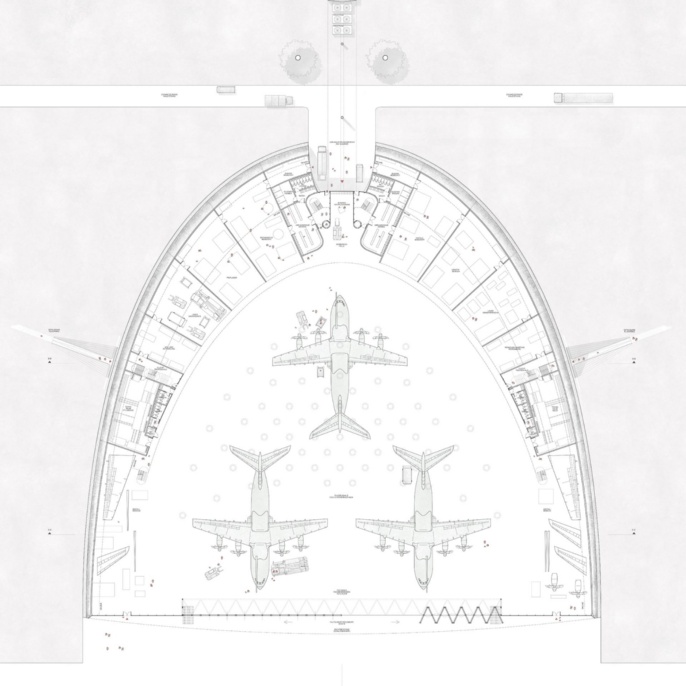

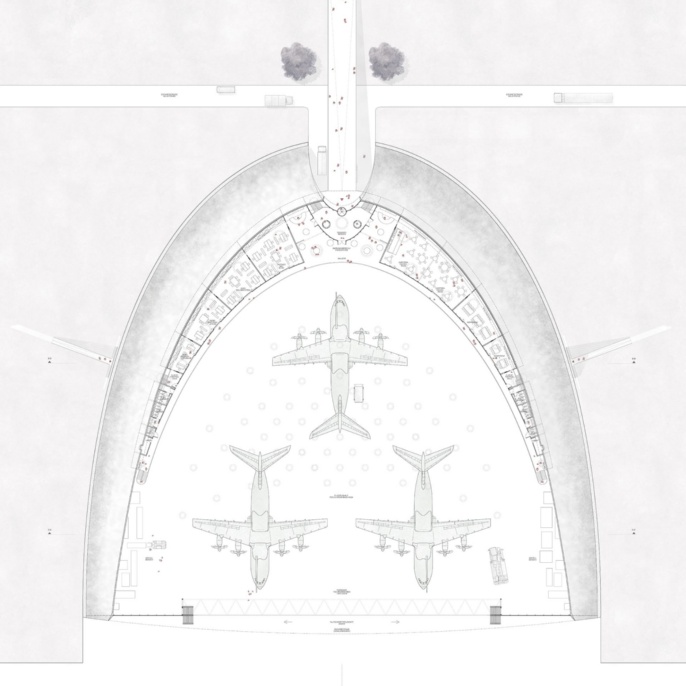

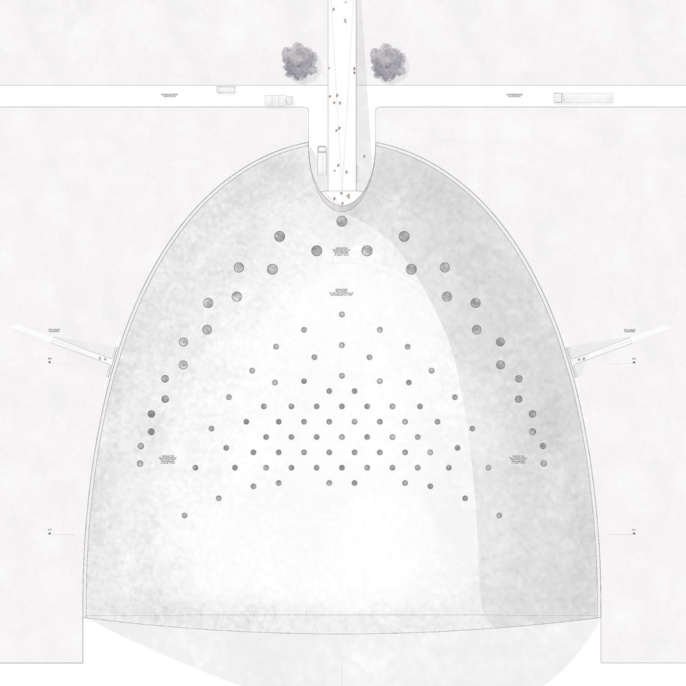

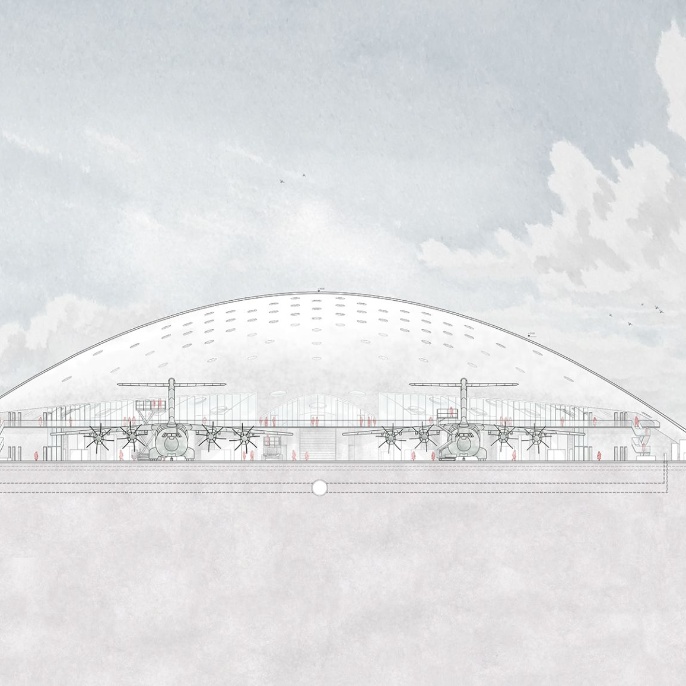

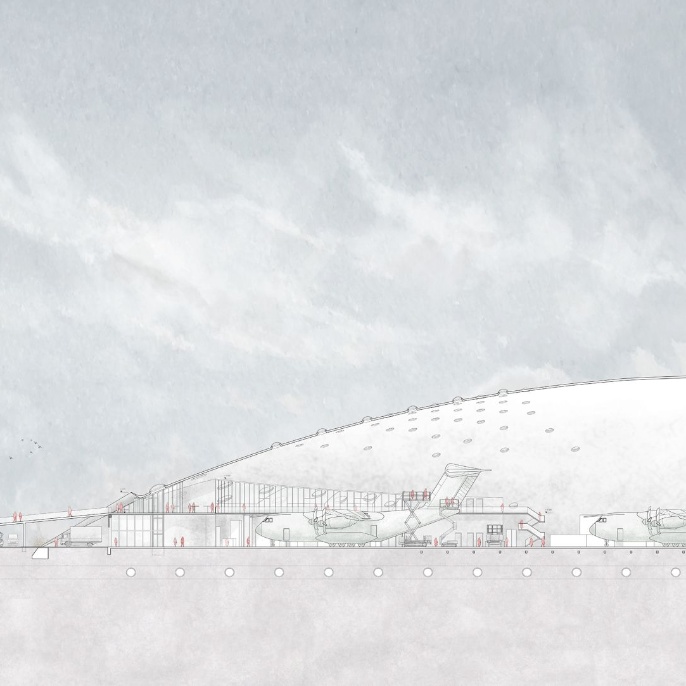

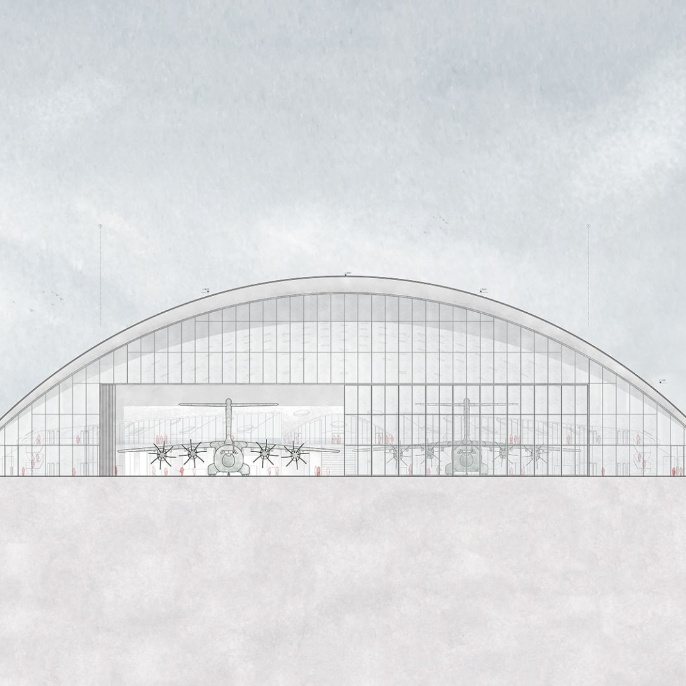

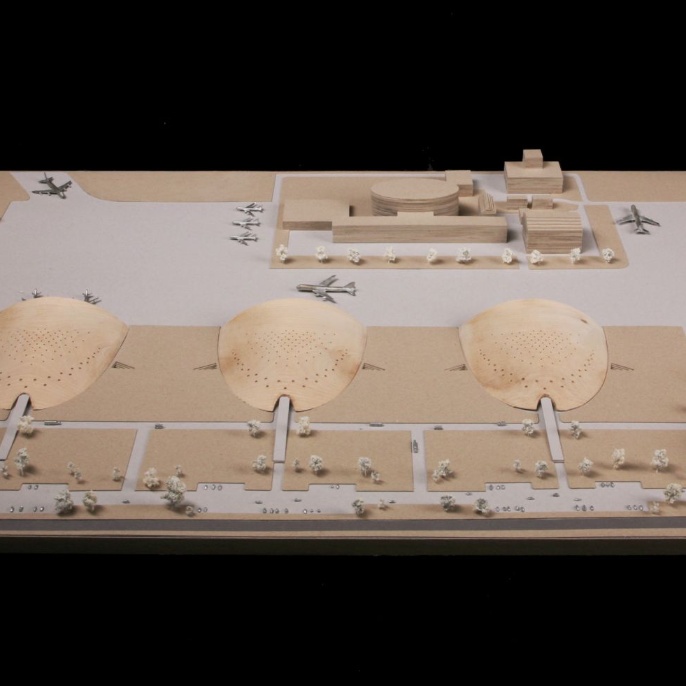

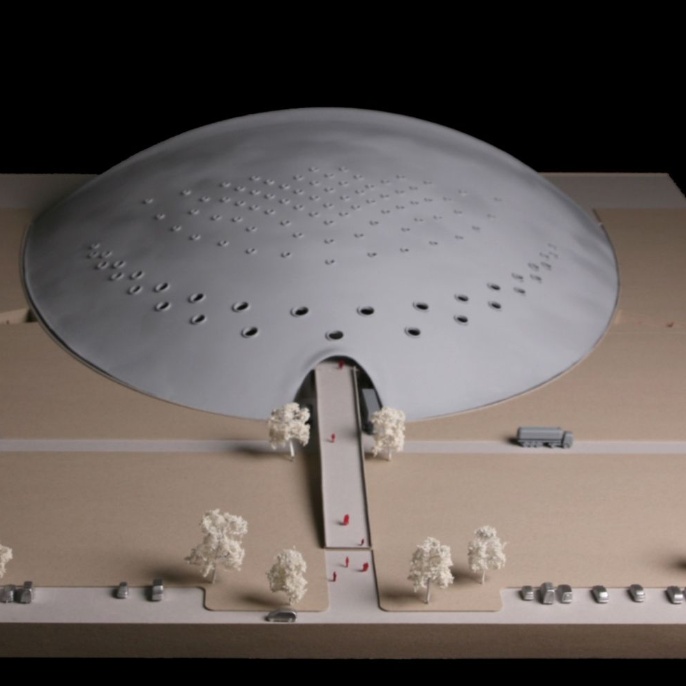

In Seville, Andalusia, the South-European center of the Spanish-European aviation industry, „Aeropolis“,is located. The Airbus Group produces and assembles the new cargo aircraft A400M here. Within this master design-course, a hangar or large-scale extension to the airbus-location for the A400M was to be designed, in which test versions in the development sequence of this new cargo aircraft could be sheltered and maintained. Additionally, the aircraft was to be presented to potential customers in the new hangar. In addition to the mechanical work on the A400M, space for workshops and office space was to be included. In doing so, the building had to adress not only usage-specific requirements, but also the climate-specific parameters of Seville.

Airplanes built as half-shells served as a source of inspiration for the design and shape of this project. In addition to the impressive curved shape, the shell geometry allows a minimal use of material with an extremely low static height compared to the usual construction methods. With an average static cross section of only 25 cm, the construction elegantly spans 140m in the longitudinal and 138m in the transverse direction. Basic parameters for a simple construction process lie in the choice and design of the shell geometry, which was an essential design-determining factor in the preparation.

The design and project work has resulted in a cooperation with the Institute of Massive Construction and Structural Concrete (Collaborative Research Center "Use of Textile Reinforced Concrete") by Prof. Dr.-Ing. Josef Hegger of the Faculty of Civil Engineering at the RWTH Aachen. Currently, a detailed mathematical investigation with intensive examination of the precast joints is being worked on in a master's thesis in Aachen.

Editor:

Franz Arlart

Supervisors:

Prof. José Luis Moro, IEK University of Stuttgart

Prof. Jürgen Schreiber, IBBTE University of Stuttgart

Dipl.-Ing. Matthias Rottner, IEK University of Stuttgart

Dipl.-Ing. Tilmann Raff, IEK University of Stuttgart

Dipl.-Ing. Michael Fleck, IEK University of Stuttgart

Dipl.-Ing. Knut Stockhusen (sbp Stuttgart)

Dipl.-Ing. Martin Peck, Head of Concrete Marketing South

MARITIME RESCUE STATION

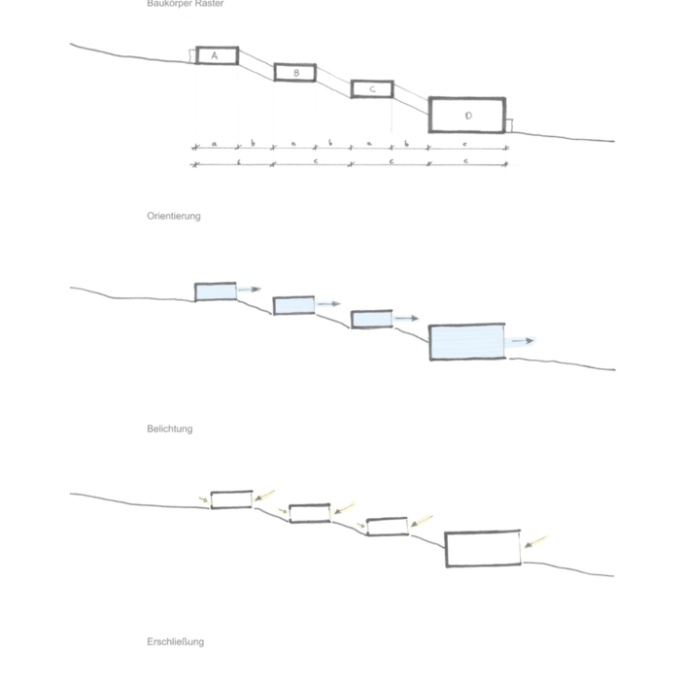

Near the capital of the Outer Hebrides in Lochboisdale at the western end of Europe a sea rescue station was to be designed. In addition to technical assistance for helicopters, first aid rooms, communication and office zones as well as residential and recreational areas had to be planned for the members of the station. The facility is detached from the practically uninhabited coast and is designed to provide the staff with an adequate quality of stay for the duration of their mission.

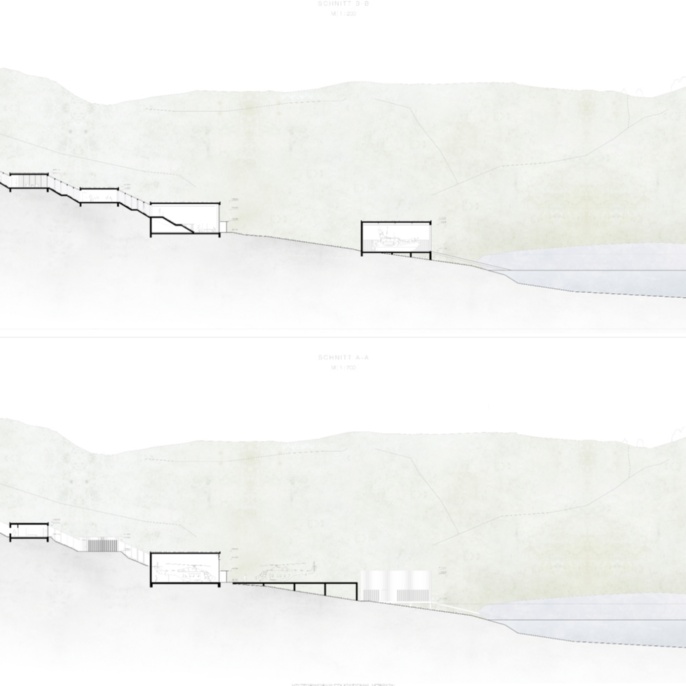

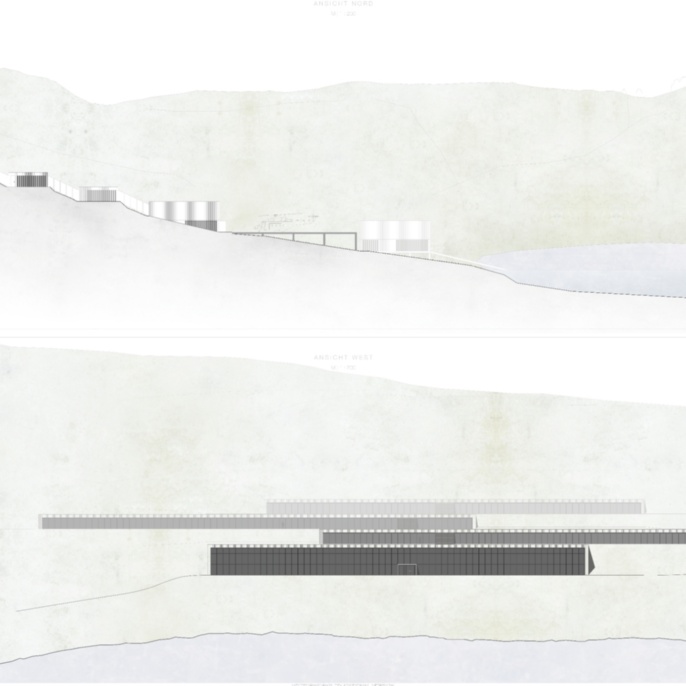

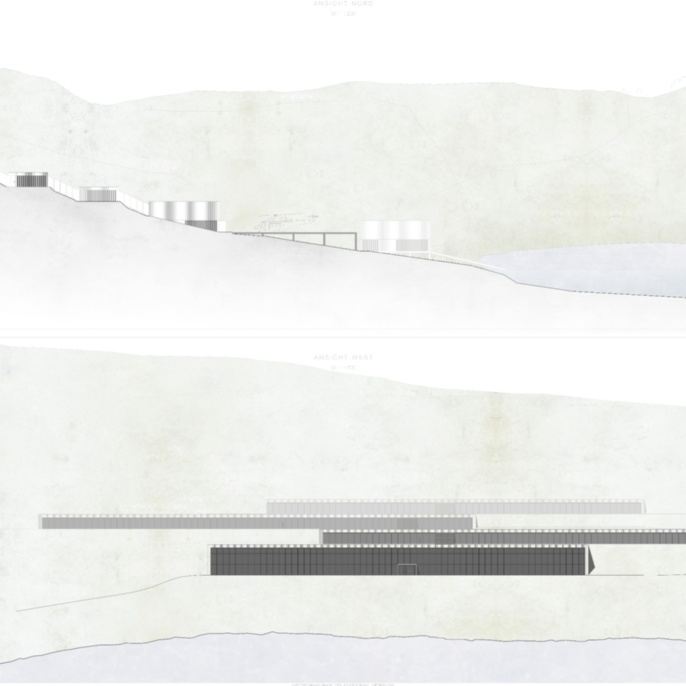

The architectural claim was to integrate the building in the environment and to keep the construction effort low. The basic concept consists out of four bars that stagger along the contour lines. These are pulled apart in the horizontal and in the vertical while connected by glass corridors. Due to the staggering along the slope, all the groups get the same quality: All rooms are oriented towards the sea and are illuminated evenly and naturally. The development of the rooms is organized from the back. The bars are accessed via glass corridors. By shifting the bars in the horizontal there is an interlocking with the landscape. There are protected living and outdoor areas. The displacement of the bars takes place in a 4.50 m grid. The depth of the first three bars is 9.40m, the depth of the fasteners is always 7.50m. The depth of a bolt and connecting passage result in the depth of the fourth bolt.

Each bar contains a different usage. The first bar has a public character. It contains the main entrance and reception area, the training rooms and the cafeteria, which enlivens the first outdoor area. The second bar is private. It houses the living areas and various common areas that provide access to the outdoor areas. The third bar contains the hospital wing with a separate entrance and the operations center with access to the third outdoor area. The fourth bar brings together the large swimming pool and hangar units.

The façade idea of the design was a full glazing of the sea-facing façade. The sides are partially open to connect to the open spaces. The back of the bars are alternateingly opened and closed. This creates an exciting interior effect and still gives a closed feeling from the outside. The front façade is designed as a mullion-and-transom façade and is divided into a 1.50 m grid. The full glazing is bordered by a frame made of a vertical wooden paneling, which reinforces the orientation of the bars again.

Editors:

Lucca Brüggemann

Dennis Bui

Supervisors:

Prof. José Luis Moro, IEK University of Stuttgart

M.Sc. Franz Arlart, IEK University of Stuttgart